Marshall Aerospace have now successfully certified and installed the latest generation of lightweight cockpit armour on a NATO Air Force fleet of C-130J-30s.

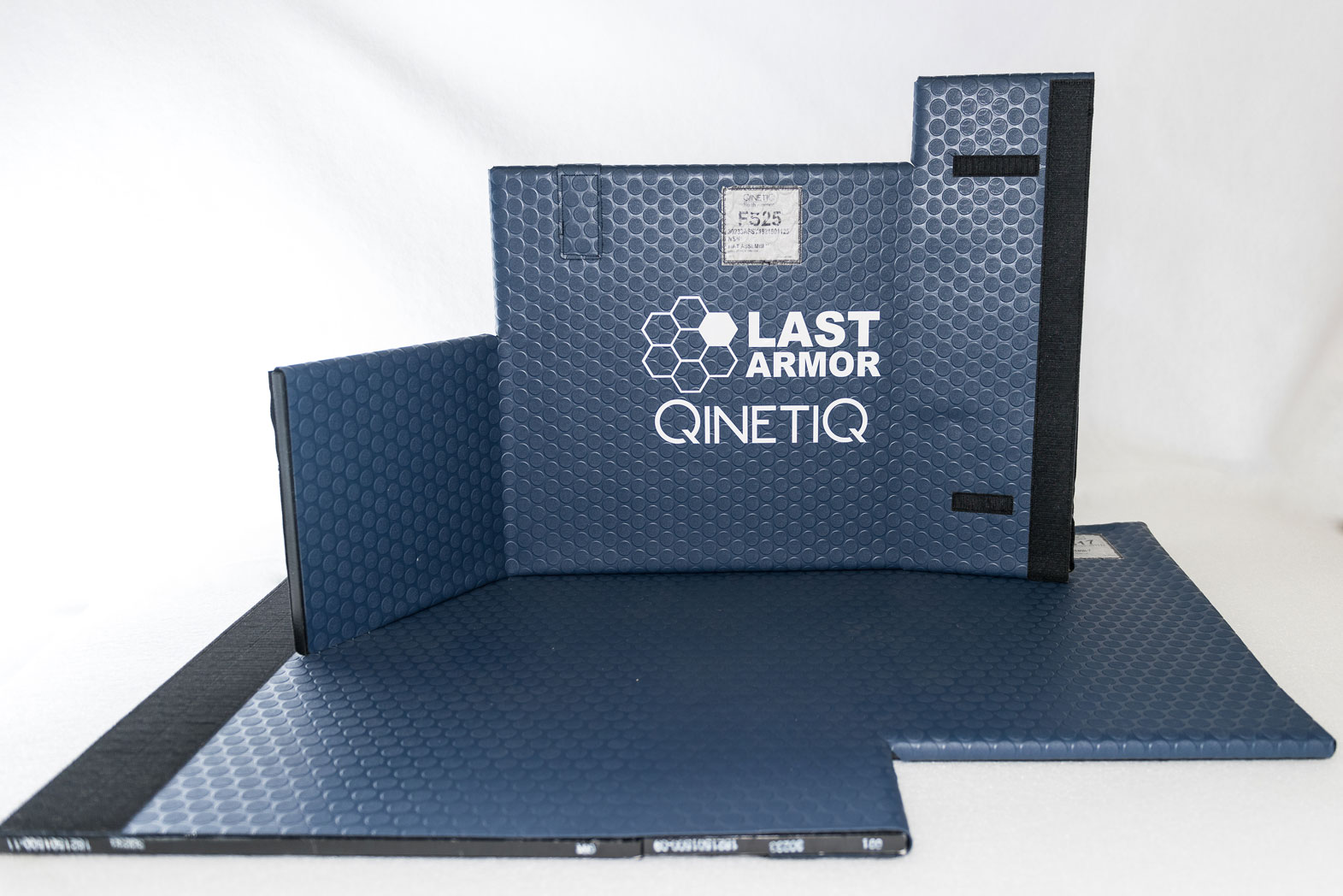

The successful in-service use of the new armour followed the signing of an exclusive agreement in July 2020 to market, sell and install new lightweight armour (LAST Armor® LWA) from QinetiQ Inc., at the same time making Marshall Aerospace the first company able to certify the armour on the C-130 platform.

NATO Air Force representative said:

“It was an easy decision to work together with Marshall Aerospace to certify and install the LAST Armor LWA onto our fleet of C-130Js. The level of protection from the armor provides a greater probability of mission success in harsh environments or potential conflicts and has promoted confidence in our aircrew.

"The new armour is less than half the weight of its predecessor which not only makes it easy to install, but has helped to save fuel, reduce the impact on the aircraft’s centre of gravity and allowed for full cargo carrying capacity across our fleet, whilst still meeting the same ballistic requirement as QinetiQ’s previous LAST Armor.”

The new armour is a tool free installation design that minimizes aircraft downtime and maximizes crucial military aircraft availability. The modular design also enables damaged panels to be easily replaced whilst in operation without having to replace the entire system.

Andrew Smith, Project Manager Marshall Aerospace explains,

“We’re delighted to have been able to offer this cutting-edge lightweight armour solution that is far more durable and easier to install onto the aircraft. Crew safety is paramount and critical to mission success and we’re pleased to be able to provide this important capability to the air crew through our exclusive partnership with QinetiQ.’’

The armour is manufactured from high tenacity polyethylene, making it extremely robust, and approximately 380kg (840lbs) lighter than the previous generation LAST Armor solution.

This combined with its environmental coatings ensures that the armour remains relatively inert throughout its service life, even when operating within the harshest of environments.