Sustainability

At Marshall we put sustainability at the heart of everything we do, using our unique set of skills and values to rise to the global climate change challenge.

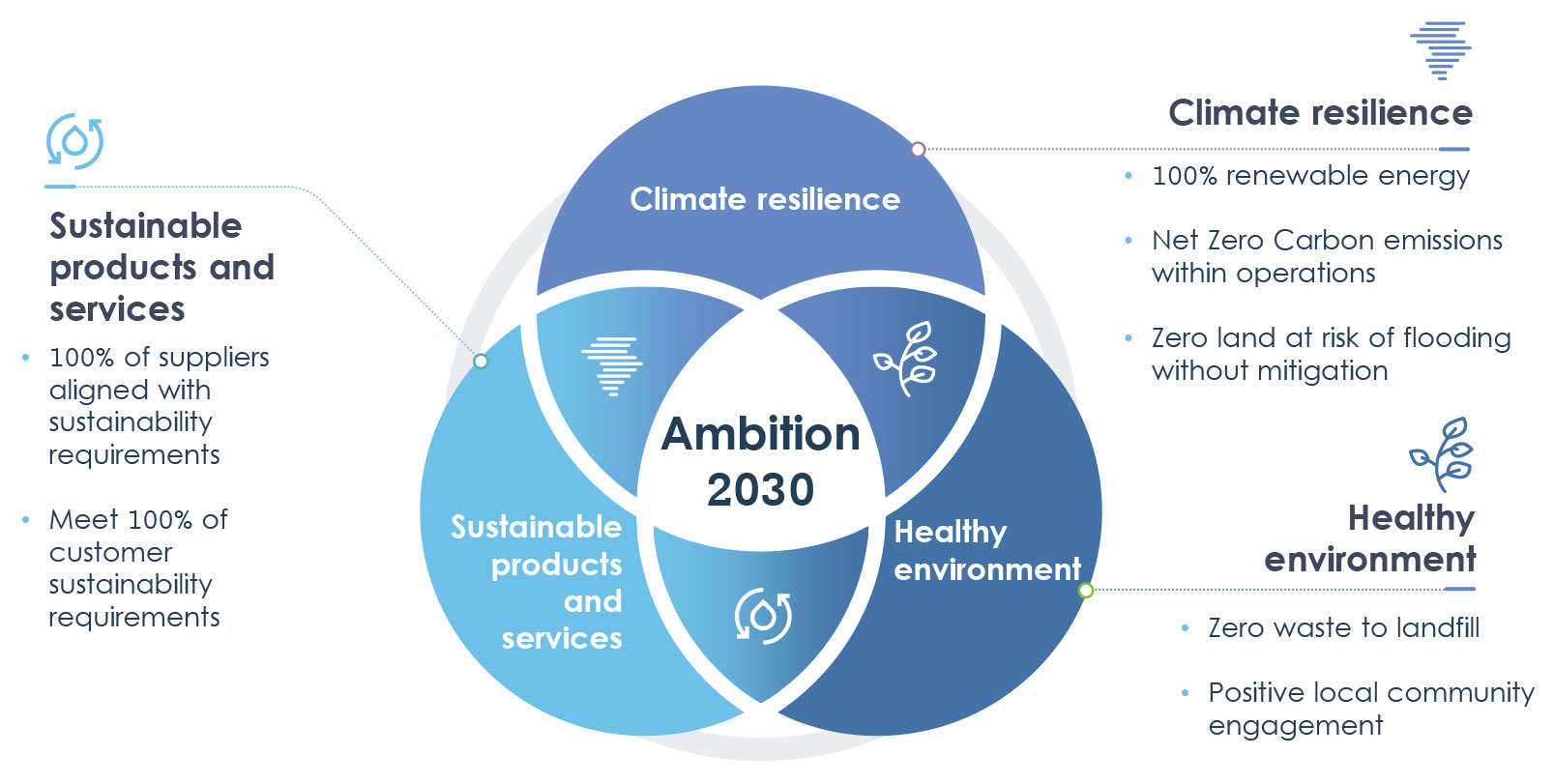

Driven by an overarching target of achieving net zero carbon emissions from our operations by the end of the decade, our Ambition 2030 framework aims to ensure that Marshall remains resilient, healthy and sustainable far into the future.

Ambition 2030 has been designed to accommodate our activity today, while incorporating and adapting to business developments and other external influences. Since the framework was rolled out, it has been incorporated into decision-making and operating practices across every part of our business.

Comprising executive and non-executive of Marshall’s Board of Directors, our Sustainability Committee provides accountability at all levels, supported by several dedicated working groups representing the full scope of Marshall’s business.

The Ambition 2030 framework comprises three key pillars, each with set objectives. Progress against these objectives is measured and reviewed at each meeting of Marshall’s Sustainability Committee, and the latest updates are included in our publicly available annual reports.

Climate resilience

We will further enhance our efforts to take climate action and become climate resilient by 2030 with reduced emissions and effective climate change risk management.

Key objectives

- Reducing emissions across our operations

- Increasing resilience to the physical impacts of climate change at key operating sites and across the value chain

- 100% renewable energy by 2030

- Net zero carbon emissions within our own operations by 2030

- Zero land at risk of flooding without mitigation by 2030

Spotlight

In 2023 we completed the relocation project of our Aerostructures business into a newly refurbished energy-efficient hangar.

As part of the design brief, and in alignment with Ambition 2030, technological solutions to improve energy performance, limit energy consumption and minimise their operational carbon emissions, were evaluated and built into the project process. As a result, LED lighting, 50kW of solar PV roof panels and air-source heat pumps were installed. The expected carbon footprint decrease from the modernisation and relocation is around 80%.

Healthy environment

We continue to help create a healthy environment to ensure that our employees, our surroundings, those of our supply chain, and the Cambridge community can thrive.

Our priorities in this area include:

- Preventing pollution to air, water and land

- Minimising the use of natural resources

- Minimising the production of waste and achieving zero general and recyclable waste to landfill by 2030

- Enhancing local biodiversity

- Engaging local communities

Spotlight

In 2023, Marshall delivered on a key commitment to implement robust environmental management systems, earning ISO 14001 certification within our core operations.

Teams across our business identified significant environmental impacts such as waste creation and energy consumption, reviewing and assessing employees’ suggestions for potential adoption. Environmental working groups were set up to determine the current environmental impact in each area, develop improvement measures, and permanently implement new systems.

Building on this success, we will continue to maintain and improve our environmental management systems in order to continue meeting the rigorous ISO 14001 criteria for years to come.

Sustainable products and services

Through sustainable design and innovation, we will continue to ensure that our business is resilient to changing customer commitments and demands.

Key objectives include:

- Incorporating sustainable design principles into our products from their inception

- Meet 100% of customer sustainability requirements

- 100% of suppliers aligned with sustainability requirements