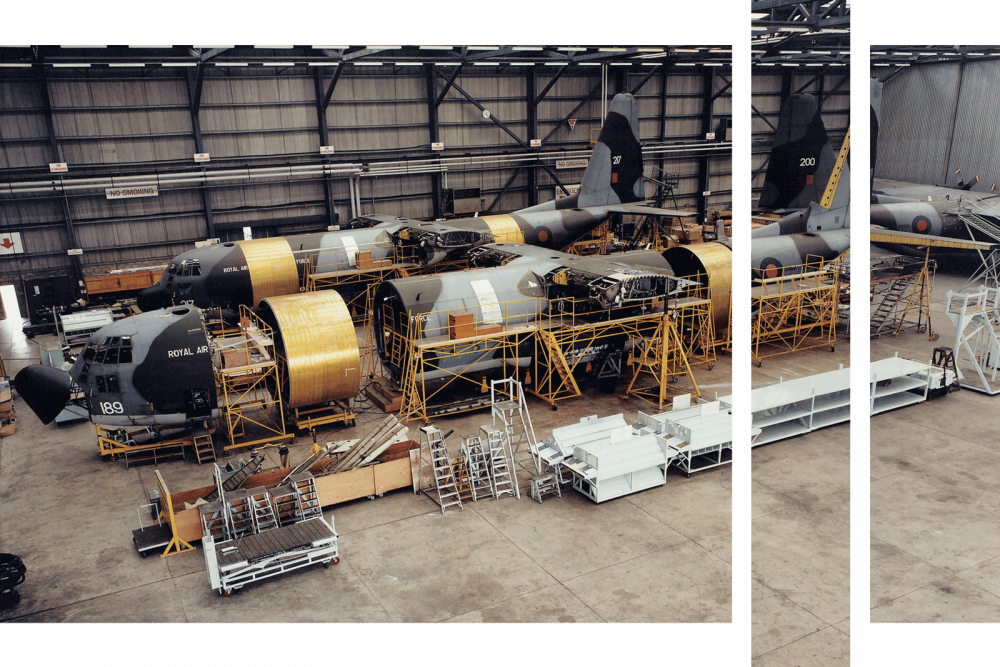

Centre wing box replacement

The centre wing box is a fatigue-life item that will require replacement to ensure the continued airworthiness of the aircraft - no major C-130 structural component attracts such a high operational load.

Marshall is recognised by OEM Lockheed Martin as the world's first authorised Centre of Excellence for centre wing box replacements on the C-130 Hercules aircraft and remains the only maintenance, repair and overhaul organisation to have performed centre wing box replacement on both C-130K and C-130J aircraft - an exceptionally complex modification that can only be undertaken with dedicated facilities, tooling and knowhow. To date, we have replaced the centre wing boxes on more than 70 legacy C-130 aircraft and, more recently, eight C-130J aircraft.

"We are incredibly proud to have added yet another world-first to our C-130 engineering credentials. This recognition from Lockheed Martin reinforces our position as an industry leader in non-standard repair and replacement, and demonstrates the strength of our capability enhancement offering."

Bob Baxter

Chief Growth Officer, Marshall

The latest Enhanced Service Life (ESL) centre wing box produced by Lockheed Martin boasts significant structural enhancements, offering a fatigue life approximately double or triple that of the C-130J’s original centre wing box.