In 20 years since joining Marshall, Jon Burnip has progressed from a university placement to the role of Aerospace Chief Technology Officer (CTO). Along the way, he has held a range of roles ranging from design engineering and stress analysis to durability testing and systems engineering.

Jon is now responsible for developing and implementing Marshall Aerospace’s technology roadmap, focusing on future product opportunities and new services for our customers.

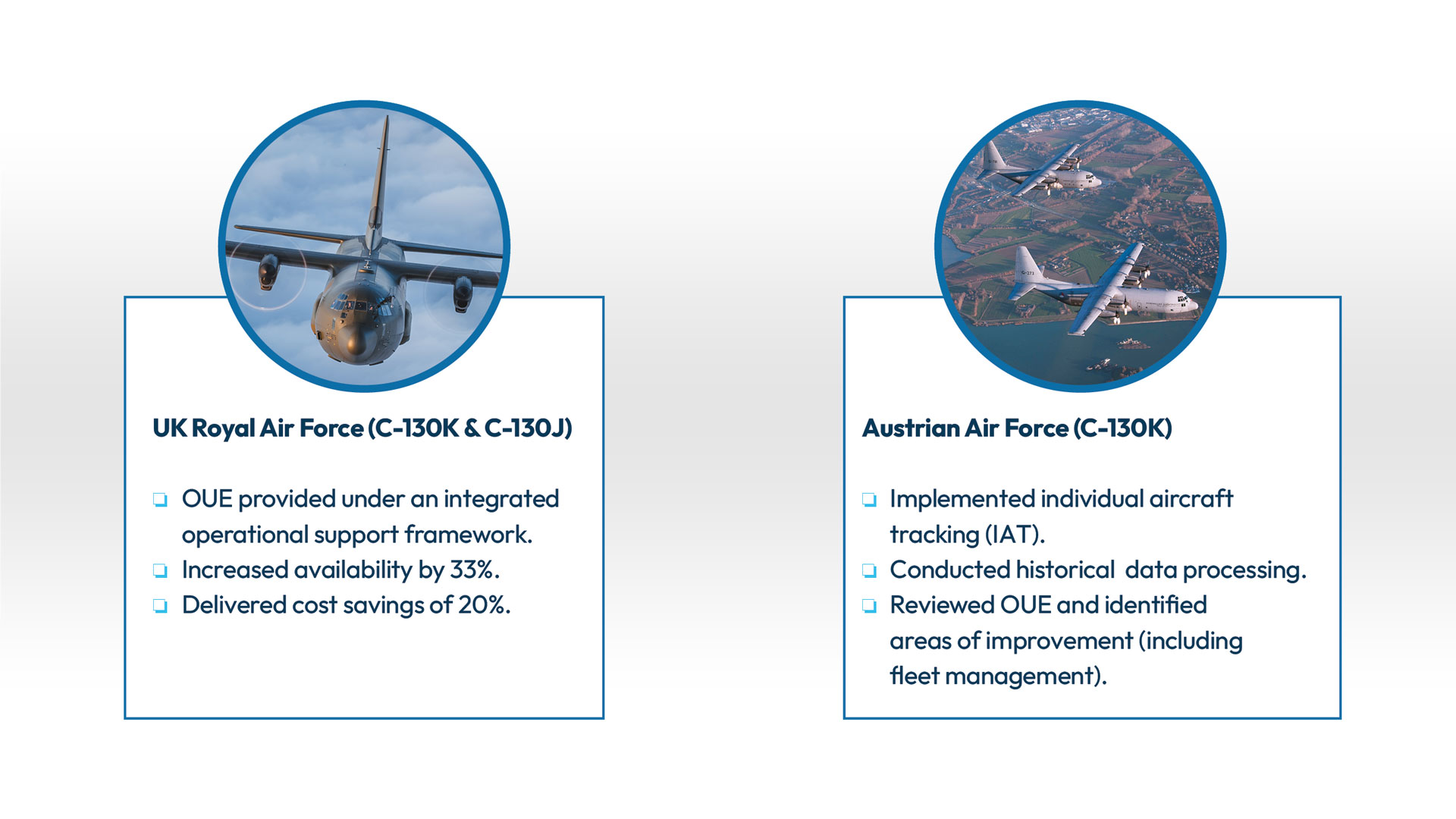

Marshall Aerospace currently supports 17 C-130 Hercules operators who field very different fleets but share one common goal: maximising aircraft availability.

As explained succinctly by the United States Air Force Materiel Command, “even modest improvements in aircraft availability can serve as a powerful force multiplier” by increasing the number of mission-ready aircraft at any given time while extending their lifespan.

Innovative maintenance tools and processes have led to many incremental advances in aircraft availability over the decades, but in our experience the most dramatic improvements can be achieved through data-driven optimisations.

In this article, I will introduce a suite of tools and processes developed by Marshall, in line with Lockheed Martin requirements, to monitor and evaluate C-130 usage and translate the outputs into actionable insights. Since these are well-established and have already delivered benefits for C-130 operators, they are considered to be at technical readiness level (TRL) 9.

Learning from aircraft data through Operational Usage Evaluation

Operational Usage Evaluation (OUE) is a term coined by Lockheed Martin to describe the process of assessing how an operator uses their C-130 fleet in order to identify necessary maintenance or engineering work.

Specifically, the OUE process involves the systematic capture, preparation and analysis of flight data to determine the severity of usage in comparison with a baseline. This is particularly important since a C-130 will lose airworthiness if certain “lifed articles” such as the centre wing exceed their defined lifespan or fatigue tolerances.

Lockheed Martin Service Bulletin (SB) 82-788 instructs all operators to carry out OUE for legacy C-130 models.

Lockheed Martin has specified a range of operational data points for the OUE process, including flight duration, average cruise speed, average time at provided altitude thresholds, aircraft pressurisations, landing parameters and aircraft weights data including fuel usage, cargo and airdrops.

The practical applications of OUE extend far beyond planning the replacement of C-130 lifed articles. If successfully implemented, OUE can drive availability improvements through:

- Prediction of likely emergent work or complex procedures, allowing advanced planning

- Identification of expected long lead parts, allowing advanced procurement

- Optimisation of necessary maintenance tasks

The quality of OUE output received from Lockheed Martin depends substantially on an organisation’s ability to understand and carefully prepare input data. Marshall offers mature, tested tools to support and streamline the process of generating and updating OUE, and for reviewing and refining OUE output together with aircraft operators.

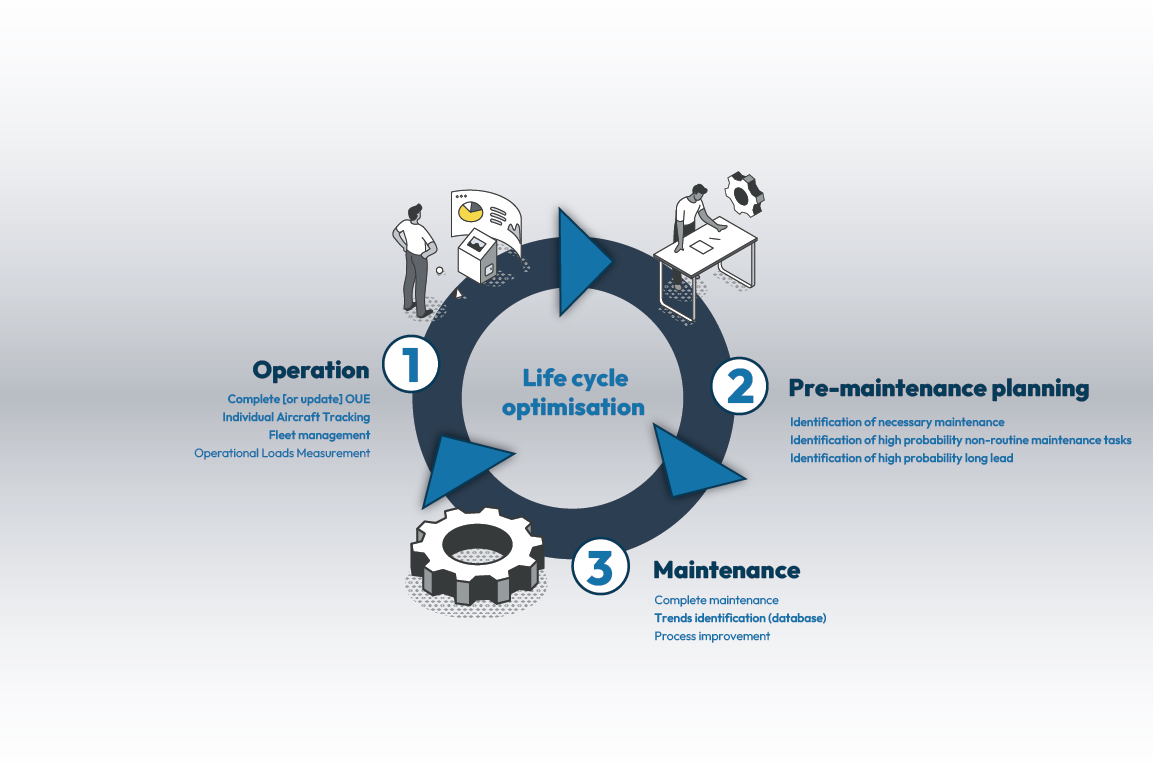

Operation phase

During this phase, operators gather in-service utilisation data from their aircraft, which can be applied to predict maintenance needs and, where appropriate, manage the fleet to avoid over- or underutilisation.

Due to the nature of military transport operations, discrepancies commonly emerge between usage as designed and usage as operated. These discrepancies tend to become more pronounced over time, depending on factors including where aircraft are deployed or (as is commonplace for platforms such as the C-130 Hercules) the number of roles and mission types flown.

Outputs of OUE include aircraft life in Equivalent Baseline Hours (EBH) and usage severity factors, both of which are used to monitor fatigue life accrual. For transport aircraft such as the C-130, several crucial structural lifespans and inspection intervals are expressed in terms of EBH. Therefore, high-quality OUE and usage monitoring from the operation phase provides an accurate basis for determining necessary maintenance activity.

Pre-maintenance planning phase

The objective of this phase is to optimise the planning of future maintenance. This includes predicting high-probability non-routine maintenance and procurement activity, while also identifying and excluding unnecessary maintenance activity.

Accurate usage monitoring can help avoid:

- Overestimation of fatigue life accrual, which may lead to additional, unnecessary or early maintenance being planned, resulting in longer maintenance inputs.

- Underestimation of fatigue life accrual, which may lead to missing necessary maintenance, increasing airworthiness risk and potentially harming aircraft availability due to in-service findings and out-of-phase maintenance.

In addition, within any maintenance activity there is a portion of emergent, unplanned work. This is where damage or failed systems are found during inspection which are not part of the baseline maintenance, but must be remedied in order to return the platform to an airworthy state or prevent future out-of-phase maintenance or downtime.

The impact of emergent work can range from delayed delivery to increased cost for expedited spares or inventory increases.

Operators can therefore can unlock further benefits by combining OUE outputs with structured databases of non-routine maintenance tasks. This allows prediction of high probability non-routine tasks and long lead parts requirements, and a basis for reforecasting usage-based maintenance tasks.

Maintenance phase

During this phase, recommendations from the previous two phases are put into action through scheduled or unscheduled maintenance.Just as importantly, information gathered during the maintenance process itself can also be used to inform future maintenance. When an aircraft is in maintenance, the data from the types of task performed—and the outcomes of those tasks—can provide valuable insights that will help predict the needs of aircraft with similar profile in terms of age and operation patterns. Baselining the emergent work against accurate OUE and IAT data improves the quality of any emergent work forecast for subsequent maintenance inputs.

Working with 14 global customers on legacy and current models, Marshall has a comprehensive understanding of the maintenance needs of C-130 aircraft. As a digital organisation, our databases of information are continually expanding, enabling optimised maintenance.

Building Individual Aircraft Tracking into OUE

Improved forecasting can be achieved by implementing Individual Aircraft Tracking (IAT), a well-established maintenance and fleet management approach that applies mission-based usage severity factors on an aircraft-by-aircraft, flight-by-flight basis.

This allows operators and maintenance organisations to identify aircraft that experience higher loads or unusual usage patterns, prioritise inspections, optimise structural life management, and reduce unnecessary downtime.

Marshall has developed in-house processes to remove the complexities of IAT activity for operators, while integrating IAT into periodic OUE review and ongoing fatigue usage reporting. Together, these tools form a suite that can provide basis for holistic through-life fleet management and maintenance planning.

The importance of regular OUE

OUE provides a single-moment snapshot while factoring in prior fleet usage. Accordingly, the assumptions behind that snapshot are likely to evolve over time in line with changing operational requirements, bases of operation, mission utilization and similar considerations.

In our experience, there are several common factors that contribute to ineffective usage monitoring:

- OUE is out of date when compared with current usage.

- OUE input data regarding flight types does not capture all variations of aircraft usage.

- Fatigue life accrual is traced on a fleet average severity basis, ignoring variation across individual aircraft or sub-fleet usage.

Marshall recommends tri-annual review of OUE to ensure that it continues to provide an accurate basis for forecasting fatigue life accrual.

Marshall Aerospace’s phased approach to OUE implementation

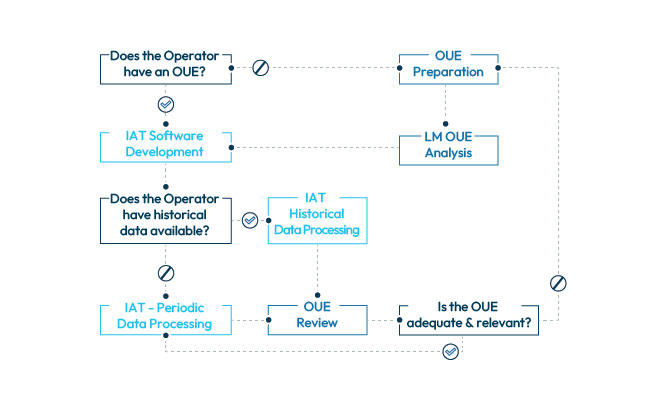

Regardless of whether a C-130 operator already maintains an OUE approach or is adopting OUE for the first time, a phased approach is recommended.

Our process flow for creation of new OUE or review of existing OUE is outlined below.

Completing this flow process from start to finish requires access to existing OUE (where available), recent flight data and historical flight data records. The activity outputs an assessment of the OUE in terms of adequacy and relevance to current operations, while also reviewing current fatigue usage monitoring processes in addition to any recommendations (such as adoption of IAT) which may improve the ability to monitor fatigue life accrual.

Once this has been completed, we can work alongside the operator to review upcoming maintenance planning and identify optimized maintenance activities, including any predicted non-routine activities. Any recommendations for management of the subject fleet to improve aircraft availability can also be provided.

Optimising the maintenance lifecycle through proven usage evaluation methods delivers measurable improvements in Hercules availability. Marshall’s experience, global customer base and close partnership with Lockheed Martin position us to help operators translate fleet data into real-world availability gains.

Whether reviewing existing processes or implementing OUE and IAT for the first time, we act as a trusted partner in maximising the life and readiness of every aircraft.

To explore how we can support your fleet, contact our engineering support team.

Marshall Aerospace’s OUE offering is delivered by a dedicated and highly experienced Aero Engineering Services team including Mark Palmer (Head of Mechanical Engineering) and Joanne Clarke (Senior Engineer – Mechanical Analysis), both of whom contributed significantly to this article.