Advanced structures and composites facilities

We can offer the flexibility of services and products that meet a myriad of needs, using a broad range of materials and manufacturing techniques.

Due to the investment in our Advanced composite manufacturing and assembly facility in Kirkbymoorside, North Yorkshire, we have a wide range of capabilities that enable us to combine the different product life cycle stages into a single programme, completely managed by our expert team.

Our composite structures are manufactured with:

- Phenolic, epoxy, cyanate, ester & vinyl ester resin systems using glass, carbon, dyneema and aramid fibres

- Employing Prepeg layup utilising Autoclave and out of Autoclave curing techniques, Filament Winding, Resin Transfer Moulding, Vacuum Infusion, Vacuum Assisted RTM

- Composite manufacture complemented by inspection, assembly and finishing processes ranging from Non-destructive testing, mechanical assembly, electrical assembly and painting

- Developing and employing additive manufacturing techniques

- Rapid prototyping and data insight on products being created

-

List of specialist equipment

Additive Manufacture 3D Printer Fortus 450MC with carbon capability Assembly Complex IPC620 / mechanical assembly*

Bonding (Heat cured & room temperature)MK D1500 Electrical Test Unit Autoclaves Autoclave 1 2.1m Diameter x 15.2m Long. 2000C and 7 Bar Max Autoclave 2 2.5m Diameter x 4.2m Long. 2000C and 7 Bar Max Autoclave 3 750mm Diameter x 700mm. 2000C and 8 Bar Max Clean Rooms Clean Room (2 off) ISO 14644-1:2015 ISO Class 8 Cloth Cutting Machine Zund Alphacam CNC 3.0m x 1.5m

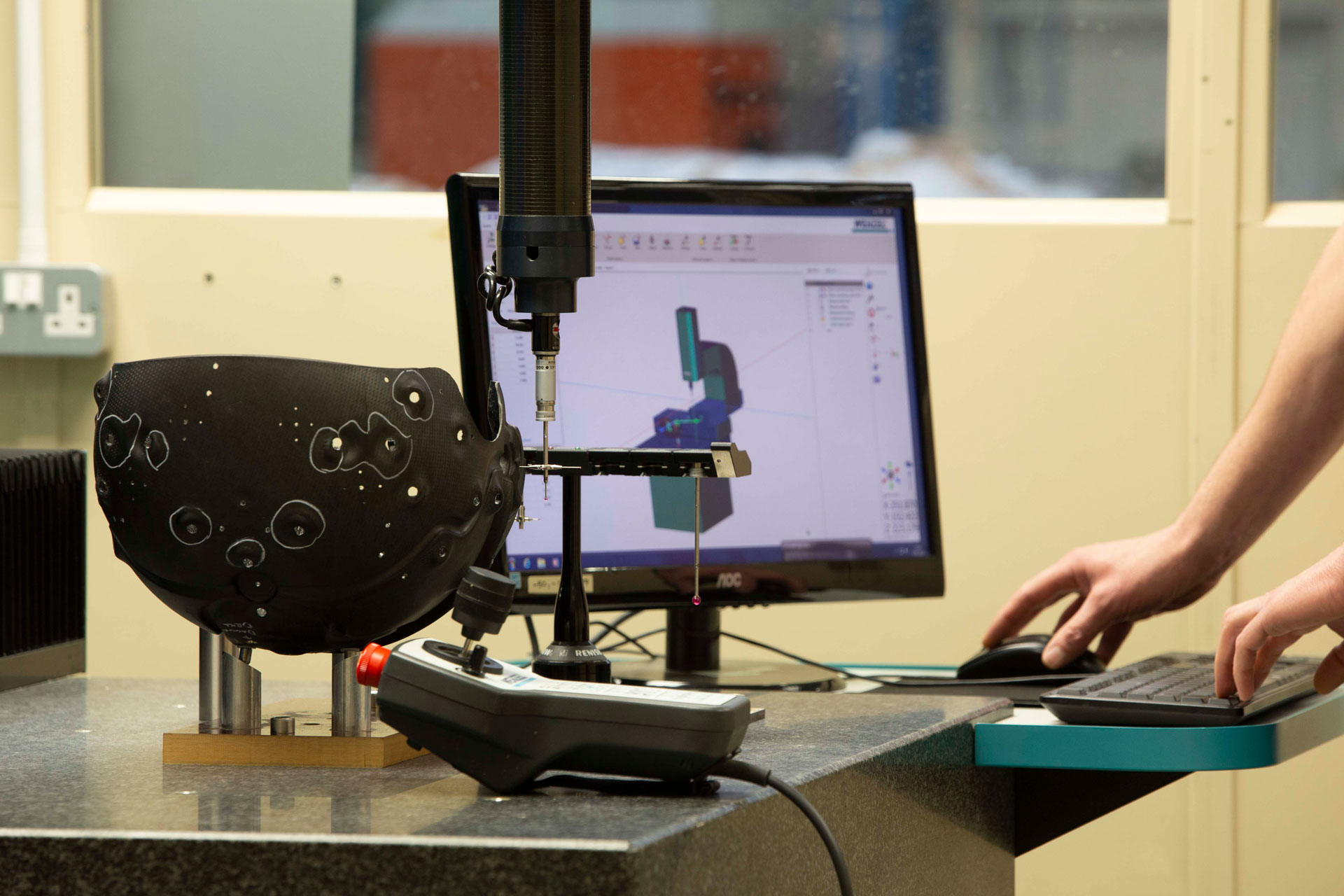

Environmentally controlled roomInspection NDT - Woodpecker

NDT ScanningC Scan unit is a wheel

Probe 2 3 x A Scan units

*We have the capability to do

Bond Testing and have used

FPHASEDARR to provide A, B & C Scan Capability3D Scan 16.6m3 Faro Arm 3m Arm Wentzel Coordinate Measuring Machine (CMM) 750mm x 750mm Sokkia Total Measurement System Olympus portable ultrasonic

thickness measurementOptical measuring system Testing Instron 5969 Materials test Machine 2 x Load Cells, 10Kn & 50Kn capacity Enviromental Chamber 350 °C max Triton Technologies TTDMA Dynamic Materials Analysis Machine Tension, Flexural, Short & Long Beam and Compression Testing Perkin Elmer Pyris DCS 6 Ancilliary Equipment Machining 5 axis CNC CNC Machine is a CMS Antaris with a 2.5m x 1.6m Bed Size Digital Lathe 1 5m x 860mm Diameter Harrison 700mm x 400mm Digital Lathe 2 Digital Milling Machine Milling Sheet Bender Booster metal bender and cutter Ovens Ovens (5 off) Maximum size PL016 - 360 degree Box Oven (3.8m x 3.5m) PL290 - Oven (3.5m x 7.9m) PL141 - Oven (1.8m x 2.4m) PL064 - Oven (1m x 0.5m) PL123 - Oven (10m x 5m) Simulation CATIA CPD CATIA v5 Surface Treatments Spraybake Paint facility Spray Booth 2 No. Junair Vehicle Spraybooth Paint facility Spray Booth Ovens (4 off) Ovens with QADS - EVAC

1 No. Junair Vehicle Spraybooth Oven - Chest Extraction

1 No. Junair Preparation Booth

1 No. Paint Mixing Room

1 No. Dust Extraction SystemShot Blasting 1 900mm x 750mm Shot Blasting 2 1400mm x 1500mm

Testing

Whether we’re designing your structures or building your designs to print, we’ll work with you at every step to ensure the end product is compliant, certified and fit for purpose.

In recent years, we’ve continued to invest in our equipment and people including additional manufacturing capabilities, design software, inspection and mechanical test capabilities and non-destructive testing. In parallel, we have an ongoing R&D programme developing new approaches to prepare ourselves for future requirements.

Our tools and equipment allow us to study the mechanical properties of materials under a variety of conditions from -190 °C to 600°C.

Using purpose-designed accessories combined with approaches such as defined-humidity testing or immersion in fluids, we can undertake comprehensive dynamic mechanical studies of a material's properties with exceptional ease.