It’s easy to assume that aerospace engineering projects follow a linear path from start to finish. In reality, Marshall sees engineering as a cycle of constant improvement based on each customer’s ever-evolving needs. John Davis, Head of Service Development – Aero Engineering Services, explains how we should see the end of every job as the beginning of the next.

John Davis is Head of Service Development within Marshall’s Aero Engineering Services business line.

Prior to joining Marshall in 2016, John was Head of Engineering Support & Service Solutions at Selex ES (UK), now part of Leonardo S.p.A.

John began his career as a test and evaluation apprentice with the Royal Aircraft Establishment (RAE), where he became an experimental flight test engineer. When the UK MoD formed the Defence Evaluation & Research Agency, he transferred with Experimental Flying to Boscombe Down where he continued to work on rotary wing aircraft test programmes including the UK WAH-64 AH Mk1 Apache.

John is a graduate of Empire Test Pilots’ School’s Rotary-Wing Flight Test Engineer Course and later became a course tutor at the school. John has a deep knowledge in support and platform level services including test and evaluation, modification embodiment, and service delivery—both in the UK and at international customer locations.

How would you summarise what Marshall’s engineering team offers customers?

Aero Engineering Services revolves around making sure our customers have aircraft that are serviceable, airworthy and fit for intended purpose.

This is true whether we’re designing a modification to enhance the roles an aircraft can perform (for example, adding new capabilities such as stores launchers, sensors or communications equipment) or planning an upgrade to improve in-service life such as a major mission systems or structural overhaul.

It is essential through our design and support engineering that we have provided a safe system that is fit for purpose and we have discharged our duty of care, particularly towards the end user or operator, who may be called on to rely on our work in high risk operations.

In practice, this boils down to three key factors: availability, reliability, and safety.

Availability means the probability that a platform system can operate when called upon to do so for a particular mission or operation. Reliability refers to the probability that a system successfully operates for the required time under the specified conditions. Safety is critical to ensuring that the equipment and services delivered are fit for their intended use.

How do you approach the process of working with a customer to design and implement an engineering solution from start to finish?

I’d say the answer lies in rejecting the word “finish.” An engineering project for a specific customer only truly finishes when they decommission and dispose of an aircraft or a capability.

In reality, almost every piece of engineering work we provide for a customer is actually part of a constantly evolving cycle that looks quite similar to the “user-centred design” cycle that’s in use across multiple industries. A typical product life cycle will comprise about 5% requirements capture; 20% design, test, evaluation and certification; 70% in-service support (including initial and continuation training) and 5% decommissioning and disposal.

Can you walk through the individual steps in this cycle?

The cycle starts with requirements capture, which means understanding the usage context for the capability, while clarifying the needs of key operational, financial and political decision-makers.

We don’t just get this information from leadership (as important as that is); we also we speak at length to end users including pilots and operators, maintainers, operational requirements taskers and many other stakeholders to get a sense of what that customer is being asked to do by their country that they can’t currently achieve. We must also consider the past, present and future composition of their fleet; the missions and usage patterns; and how the customer’s organisation itself is structured to support all of this.

None of these things are static. If we are working with a new customer, the background research and relationship-building will be critical. If it is an existing customer, we must consider how their situation may have evolved since the last time we embarked on a new or evolved programme with them and what the impact of that evolution might have been.

In many cases, the customer will paint a picture of gradually shifting requirements related to their existing organisation or assets; but sometimes they’ll have identified an entirely new need for a capability they didn’t have before, and will ask us to help them meet it. We have to be open to both possibilities and agile in our thinking.

The next step is for the customer to specify their requirements. This can either mean working with them to jointly define the requirements of a problem they are trying to solve, or it could be that they release a statement of requirements for the capability or operational gap for open competition. Either way, trust is really important to success at this stage as it ensures we can match their needs and requirements to our engineering capabilities.

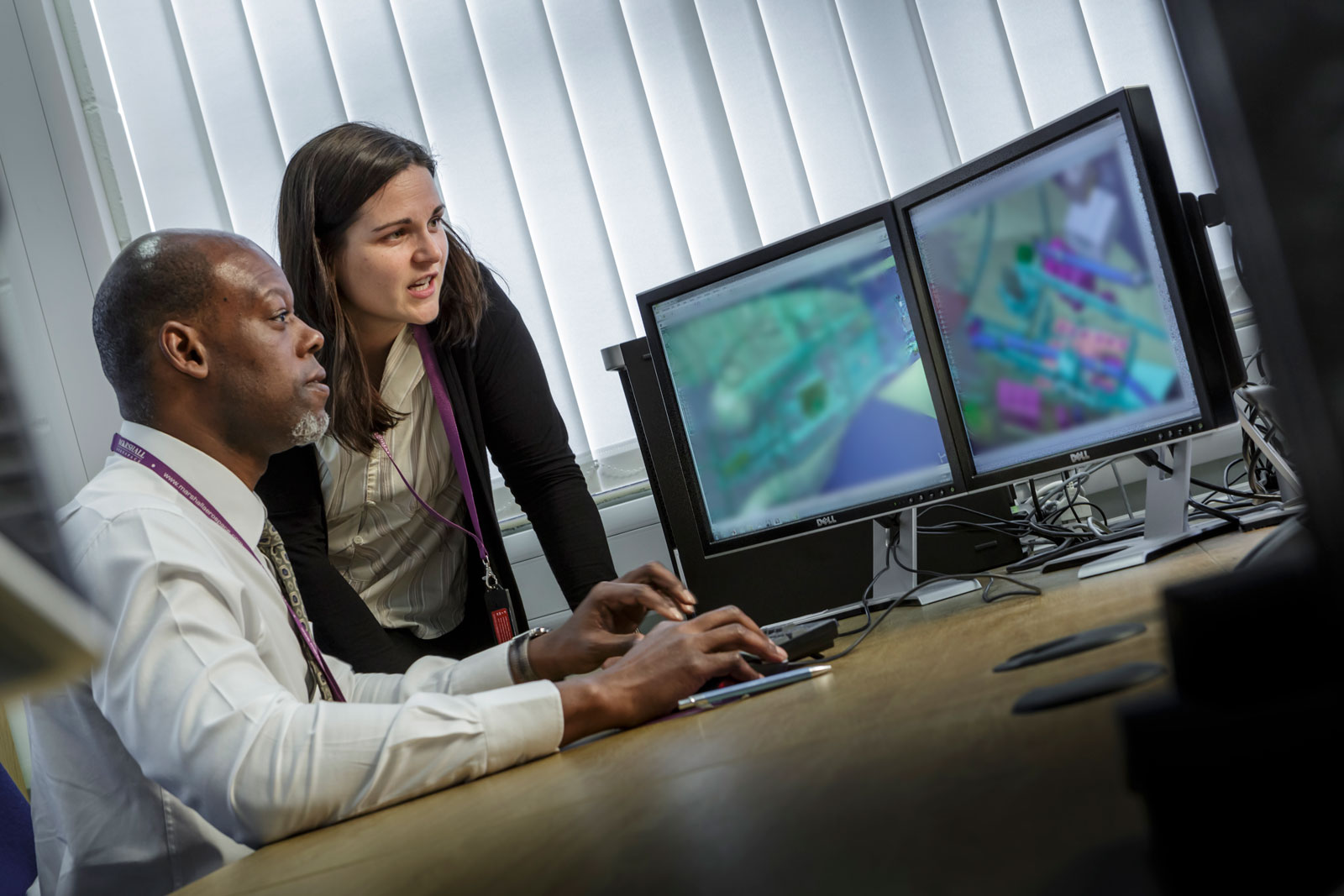

By this point in the cycle, we’ll know our customer well and have developed a good idea of what they may need from us. We then move on to design, test, evaluation and certification. With the customer’s requirements and concept of operation understood, we then manage those needs in an engineering management tool so we can control our solution design at all times by identifying and solving emerging technical risks.

This phase involves working incredibly closely in merged teams to evaluate and adapt our proposed engineering solution into something that will work for everyone. In many cases where the solution is being competed and access to the customer community is controlled, those in Marshall through their previous careers in the UK armed forces and MoD are highly valuable in helping ensure that the solution we design can be safely and easily used by those who will operate it. This lies at the heart of Marshall’s constant design philosophy to “protect people in critical situations.”

By the end of the design phase, we will have developed a service, physical equipment or a new capability. This then needs to be put through a test and evaluation (T&E) programme to prove it meets the customer requirements, and is safe and commercially compliant. T&E can be physical, digital or (more usually) a combination of both, and is frequently progressive throughout the programme. It is not uncommon for specific T&E events to be witnessed by the customer as part of the acceptance process.

A key part of any solution is planning for entry into service. If the programme is a major avionics upgrade or a significant structural life extension, careful fleet planning with the customer to sequence the work will be required to ensure that the end user always has a deployable level of residual capability as the solution is rolled out. How many aircraft (and which aircraft) need these upgrades? How should the upgrades be sequenced? How should the new equipment and all customer community stakeholders (operators, maintainers, logisticians etc) be brought together through respective training programmes to establish the new capability in-service?

End user training is also central to achieving a smooth entry into service. At this point, Marshall’s design teams must transfer their own knowledge of the product or capability to the end user community in a form that they can readily assimilate. It is normally at this point, with an initial capability deployed, that customer acceptance of Marshall’s work is complete and the in-service support phase commences.

We offer customers a full range of in-service support solutions. On one end of the scale, customers can opt for relatively simple spares, repairs and post-design support, which means they will retain control of risk. The opposite of this is a turnkey solution where all the equipment availability and reliability risk is transferred to Marshall as the provider.

Regardless of the solution selected, large amounts of usage performance data will be generated for the product and/or capability supplied and the support services we are delivering. A variety of technical and business analysis techniques are applied to this data, and the output is used to prove commercial compliance and meet payment plans, identify reliability and service improvements, and build the evidence for the next capability upgrade or technology insertion.

This leads us back to the first step of the cycle: understanding the context of use. Again, there is no “job done” – there’s just a cycle of evolving customer needs and how we meet those needs.

Given the cyclical nature of the work Marshall does for customers, how frequent does contact need to be between organisations?

I’d argue that the most successful relationships are the ones in which we can work together constantly to understand the need, agree on the solution and assess its effectiveness. Our air platform integrated operational support (IOS) contracts in the UK have been highly successful in bringing together our UK MoD customer, armed forces end users and industry in a relationship centred on partnership behaviours. Obviously not everyone may find that level of depth necessary, but these underlying behaviours are in Marshall’s DNA and lie at the heart of what we deliver for any customer.

A perfect example might be the support Marshall has provided for the Royal Netherlands Air Force (RNLAF) ever since we delivered a very complex cockpit and cabin safety upgrade programme on their four C-130H aircraft in the early 2000s.

When the upgraded aircraft were put into service, we jointly agreed to establish a dedicated team of five individuals within Marshall to provide a 24/7 engineering “support to operations” service. The team is based in the UK, but works solely with this customer and maintains daily contact with the front-line operators and the RNLAF C-130 airworthiness engineers. Backed up on an as-required basis by the wider Marshall AES organisation, this team has resolved a wide variety of defects for the RNLAF—irrespective of whether an aircraft is at Cambridge undergoing maintenance or has become unserviceable at a globally deployed location in a critical situation. This approach to working with RNLAF has been highly successful, and we’re delighted to have renewed our engineering support contract with them earlier this year.

We provide similar technical engineering support services to other customers, ranging from embedding liaison engineers in depth maintenance organisations that serve air forces to providing direct on-site support at a customer’s front-line location.

Is it important that all the physical engineering work on a project is done at Marshall by Marshall people, or can some be done in-country?

We’re absolutely open to discussions around dividing physical engineering work between organisations and across locations: obviously certain procedures like major aircraft conversions or upgrades can only be generally performed by us in Cambridge due to highly specialised requirements, but that’s not always the case.

For example, we’re currently working with the South African Air Force to upgrade the avionics systems on their fleet of legacy C-130BZ aircraft. Marshall designed and certified the original upgrade to the SAAF C130BZ fleet in the late 1990s and now, due to obsolescence, upgrades are required to sustain the aircraft in service. In this instance, we have designed the modifications to remove the obsolescence and are implementing them in the first two aircraft at Cambridge, as well as testing and verifying our upgrade. We’re then supplying service bulletin kits containing all parts, components and instructions needed to perform the same modifications on the remaining SAAF C-130BZ aircraft in South Africa. Additionally, we’re training in-country technicians to the point where they can confidently carry out the modification processes themselves.

We have a somewhat similar engineering support arrangement relating to the French Air Force’s fleet of 14 C-130H aircraft. Day-to-day depth maintenance for the fleet is actually looked after by SIAé, a state-owned maintenance organisation, but we provide SIAé with technical support on repairs, airworthiness advice, technical publications and with repair modification kits.

We also support SIAé more directly in the event of significant new repairs they haven’t encountered before. For instance, when the rainbow fittings (key load-bearing joints between outer wings and centre wing boxes) on some of the aircraft needed changing, we dispatched expert team members and leased SIAé our specialist equipment. Our team transferred knowledge by conducting the first changes and carrying out any necessary repairs, then observed SIAé when they implemented the second set of changes. This is another good example of how we can flexibly divide up when the work happens and who does it.

What would you say sets Marshall apart from others in the field of aero engineering?

I’d say that our combination of deep experience, broad capability and willingness to take on complex and difficult aerospace challenges is unique for a business of our size. These things, coupled with the depth at which we work with customers, mean that we are seen globally as an independent beacon with high levels of integrity in the marketplace.

We repaired our first aircraft in 1912 and made our first forays into aero engineering shortly after. We’ve done everything from converting, modifying and repairing aircraft during the Second World War through to designing and certifying complex engineering solutions such as converting wide body commercial transport aircraft into military tankers and freighters, testing new engines and working on a range of special-mission aircraft. The enduring enterprising legacy from our founders and forebears has enabled us to offer platform-agnostic end-to-end engineering services spanning all the way from design through to certification, testing and in-service support.

This brings me back to my earlier point about the cyclical nature of the work we do: rather than working on a single part of a single project, we can be part of a customer’s story spanning decades, working alongside them to constantly understand and meet their evolving needs. In addition to being an effective way to work, it’s also highly rewarding, but most importantly is our way of protecting them in critical situations.